Whether indoor or outdoor, pathogens and microbes like mold exist in every cultivation and present a danger to your product, your business, and your customers. Pre-harvest SOPs can mitigate microbial contamination to some extent, but without a post-harvest kill-step, you risk losing thousands of dollars in lost revenue, or worse, an expensive product recall.

Safeguard your company's license and your brand’s integrity by implementing Ziel’s chemical-free, non-ionizing cannabis mold treatment.

Pass Regulatory Compliance with an Organic Cannabis Mold Decontamination Solution

Unlike X-ray treatment, which alters the molecular structure of your product, Ziel’s RFX utilizes Radio Frequency to treat cannabis mold and pathogens organically and in line with GMP-certified and EU GMP-certified facility requirements.

With Radio Frequency mold treatment, you can expect:

- Near-zero cannabinoid loss

- Nominal loss of terpenes and moisture

- No harm to the plant’s natural enzymatic properties

- >99% regulatory compliance pass rate

saved annually using the RFX

average microbial fail rate for flower

microbial pass rate using RFX

Avoid Product Recalls

Cannabis product recalls are costly, damaging to your brand, and potentially fatal for your business if your license is revoked. The two most important steps you can take to avoid a recall are to label your products correctly and to implement the right post-harvest cannabis mold treatment. Using a safe, organic treatment like Radio Frequency, as opposed to chemicals (ethanol), gases (ozone), or ionizing radiation (X-ray), not only protects your business from a recall but improves your brand perception by aligning your flower with organic processes.

Mitigate Mold, Yeast and Other Pathogens

Mold, yeast and other pathogens thrive in the same environment cannabis does. Their growth varies between indoor and outdoor operations and depends on environmental factors, but one thing’s for certain—there are microbes and pathogens present in every grow operation. They can not only cause health problems for consumers, but they can cost you thousands in failed compliance and recall issues. Getting ahead of them with a post-harvest kill step gives your brand a leg up over those who incorrectly assume their grow is free of pathogens.

Eliminate Microbial Regeneration After Treatment

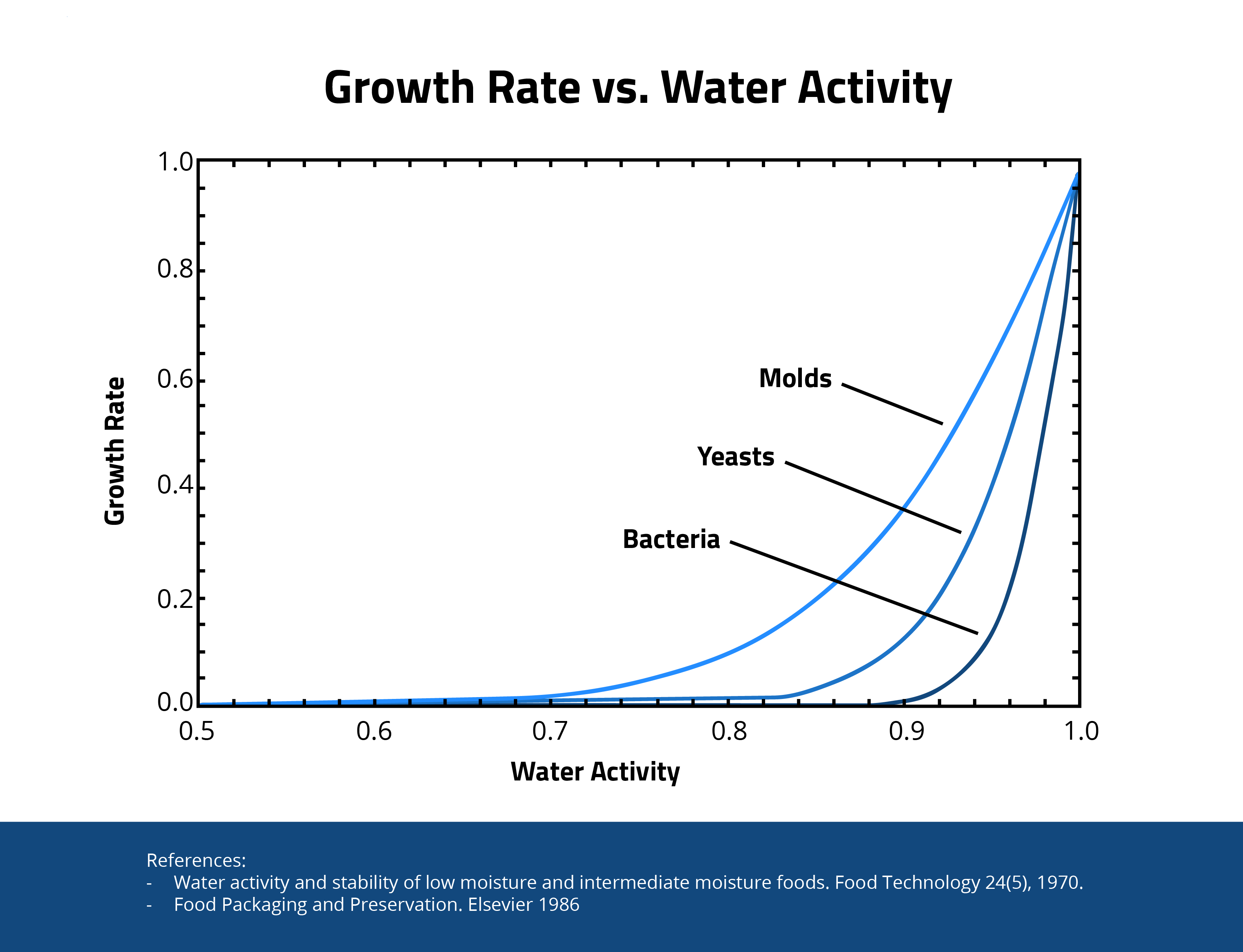

With Radio Frequency, you don’t have to worry about microbial regeneration after treatment. As the chart details, as long as the flower’s water activity level is below 0.65, molds, yeasts, and bacteria will not grow back. Certificates of Analysis can determine your product’s water activity levels to ensure you stay below regeneration levels. Plus, many states require water activity levels less than 0.65 or 0.60 to ensure product stability after placement in retail dispensaries.

Thrive in the European Cannabis Market

Europe’s cannabis market revenue is projected to hit US$6.28bn in 2023.1 That level of competition means your brand and operation need to stand out while remaining compliant and profitable. Radio Frequency mold treatment addresses all of the above by aligning your brand with organic, EU GMP-certified practices, guaranteeing regulatory compliance, and saving you from costly fees associated with other cannabis mold treatment options, like X-ray. (Germany’s BfArM requires any product treated with X-ray to attain AMRadV registration, which costs EUR 5,000 per strain and takes 12-18 months.)

Meet the RFX

Cannabis Mold Treatment Without Ionizing Radiation or Chemicals

Non-ionizing radiation and chemical-free

Treats trimmed and milled flower

14-Min Average Cycle Time

Requires no facility modifications

Treats 0.5 - 2.3 kg/batch (1-5 lb/batch)

Turn-key installation, commissioning and training

Retain plant's natural enzymatic properties

Suitable for organic operations

Nominal loss of terpenes and moisture

Up to 3 log microbial pathogen reduction

Explore all our products

Ziel designs, builds and installs processing lines with your product and requirements in mind. We partner with you to create custom process systems and solutions that meet - and then exceed - your goals.

RFX uses highly sophisticated and controlled radio frequency waves - instead of harmful chemicals - to reduce total yeast and mold count in cannabis & hemp.