Radio Frequency for Nuts & Seeds

Developed in partnership with STALAM, the global leader in Radio Frequency technology, the APEX 85 effectively reduces Salmonella by a 3 to 5 log kill without impacting product sensory qualities.

Non-ionizing radiation and chemical-free

Retains product's sensory attributes

Proven 3 to 5 log kill for salmonella

Treats up to 725-1200 kg/hr (1600-2700 lbs/hr)

Treatment time per batch: 20-30 minutes

Continuous System

3-5 Log Kill Reduction

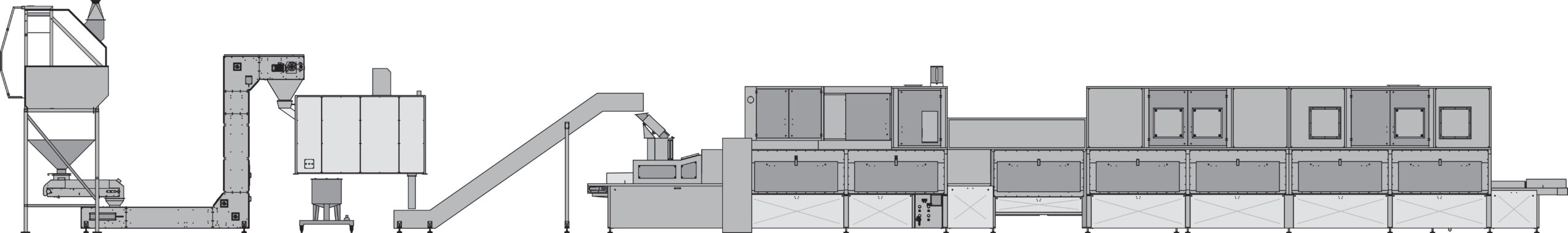

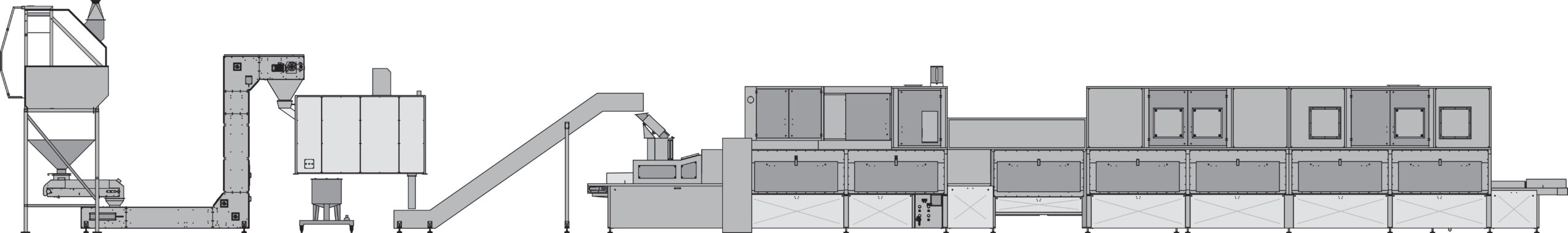

Designed and manufactured in partnership with the global leader in radio frequency technology, STALAM, the Apex 85 combines the precision of radio frequency technology with Ziel’s proprietary process solutions to effectively eliminate Salmonella, E. coli, and other microbial pathogens in nuts and seeds. APEX 85 easily integrates into automated processes and effectively reduces microbial pathogens without the use of chemicals, ionizing radiation, or steam, making a superior application for food products.

Our Technology

RF works by creating an oscillating electromagnetic field between two electrodes in the APEX 85’s processing chamber. Operating at a 27.12 MHz frequency level, polar water molecules contained in the natural moisture of the product rotate 27 million times per second, generating friction and thus the heat necessary to kill microbial pathogens. The long radio wave profile penetrates uniformly throughout the product, creating ‘volumetric heat,’ as opposed to traditional thermal heating.

Easy to Operate

APEX 85’s HMI user interface consists of easy-to-use menus of preprogrammed processing recipes, developed by Ziel on-site with your team. The system monitors the progress and temperature of each treatment to provide real-time user feedback. Data logs are generated automatically to assist in quality control monitoring and reporting. Optional remote monitoring and software upgrades are available via a standard internet connection.

Technical Requirements

| Product Applications | Nuts and Seeds |

| Processing Capacity | Treats up to 725-1200 kg/hr (1600-2700 lbs/hr)* |

| RF Power | 85 kW |

| Wash Water | Up to 60 gallons per minute |

| Chilled Water | 23° C (75° F ) water, ~20 Tons (40,000 lbs) of Refrigeration |

| RF Processing Time | Treatment time per batch: 20-30 minutes |

| Electrical Requirements | 400/480 VAC +/- 5% | 50/60 Hz | 3-Phase + Ground | ~500/430 A Connected Load |

| Codes & Standards | CE mark; UL and CSA compliant FCC compliant |

| System Dimensions | 21.9 m (L) x 2.4 m (W) x 3.3 m (H) 72' (L) x 8' (W) x 11' (H)d |

| Compressed Air | Requires clean, dry, oil free compressed air at 7 bar (min) |

| Standard Baseline System | Infeed hopper, metal detector, RF generator(s), product holding and cooling section, chiller for cooling RF generator, remote monitoring system (EWON) and SCADA |

| Regulatory Compliance | Food-grade components in all commodity contact areas |

| Material Construction | Food grade stainless steel product contact surfaces, with painted steel support structure |

| Operating Environment | Indoor location, well ventilated room 15° C to 40° C (59° F to 104° F) Relative humidity: 10% to 90% non-condensing environment |

| Other Equipment | Pre-wet section - dependent on the product to be treated |

| Warranty | 1 year limited parts & labor |

| Manufactured | Italy |

Explore all our products

Ziel designs, builds and installs our processing lines with your requirements and product in mind. We will partner with you to design and build custom process systems that will best meet your goals.

Get in Touch with Us

Learn More

Check out our Resources page and download additional information on the remediation solution you're interested in.

Contact Us Today

Take the first step to boosting your profit margins. Start the conversation now.

Meet the APEX 7

Learn more about how cannabis remediation with the APEX 7 can help your specific operation.