What Are Your X Factors?

> 99% Pass Rate

Preserves Bag Appeal

Highest Volume Throughput

Processes 160 lbs / 8 hr Shift

14-Min Average Cycle Time

No X-Ray, Gas, or Chemicals

Lowest Processing Cost

Organic Process Compliant

Treats Trimmed and Milled Flower

24/7 Equipment Uptime

Requires No Facility Modifications

The Ziel RFX is the result of 7 years’ operational experience successfully processing hundreds of tons of flower using Radio Frequency technology. We’ve now harnessed this expertise into a sleek, compact design that runs on single phase power and delivers the highest throughput in the industry.

Whether you have moldy weed or want to proactively add a microbial control step to your SOPs, you can trust the RFX to seamlessly fit into your process and preserve all the sensory qualities that makes your brand unique. The Ziel RFX is suitable for organic and GMP-certified operations.

Maximize Your Harvest To Boost Profits

Average Results With the RFX:

in recovered annual revenue

compliance pass rate for microbial testing

of flower processed daily

The Power of Radio Frequency

RF is non-ionizing, meaning it won’t change the molecular structure of your cannabis flower. Instead, it uses long radio wavelengths to create an oscillating electromagnetic field around and within the flower, reaching the core of the bud. The flower’s moisture molecules sync with this vibration and start to rotate in unison with it, turning 27 million times per second. This generates friction, ultimately creating enough heat to kill microbial pathogens, but never enough heat to degrade or decarb THC.

Ziel’s proprietary process settings in the RFX, administered by a Siemens PLC/HMI system, precisely control the heat in real time via temperature probes, reducing targeted microbials to safe levels without compromising the flower’s potency, terpene profile or sensory qualities.

Partnering With Ziel

Begin commercial operations with your RFX in less than one week of installation

When you incorporate the RFX into your SOPs, you also get Ziel’s team of scientists and experts at your disposal. We ensure your installation, commissioning, and training are complete in just 4 days. We then monitor each batch you run for the first year to help you identify patterns, troubleshoot issues and fine-tune your cannabis treatment recipes.

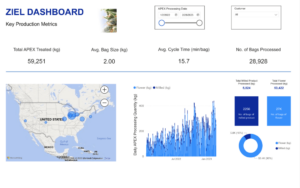

A Data-Driven Approach

The RFX does more than control microbial pathogens in cannabis. It collects data from every batch you run. Harnessing your harvest's data also provides critical feedback on your operation, ensuring post-harvest SOPs are being met, to improve product consistency, product quality, and operational efficiency. The Ziel Dashboard:

- Provides deeper insights into your product profiles

- Which of your strains is more prone to cannabis mold and pathogens (Yes, the strain makes a difference!)

- Helps monitor SOP adherence and can predict when a product will fail testing

- Assists your sales team segment your product for the market

RFX Technical Requirements

| Product Applications | Cannabis & Hemp: Dried Trimmed Flower, Milled & Trim Material (8-12% moisture) |

| Throughput | Treats 1.3-2.5 kg/batch (2.8-5.5 lb/batch) |

| Processing Time | 14-min average cycle time |

| RF Power | 4 kW |

| Electrical Requirements | Single Phase 240 VAC +/-5%, 50/60 Hz +/- 2%, 70 A Connected Load |

| Codes & Standards | CE mark; UL and CSA compliant FCC compliant |

| System Dimensions | 2633mm x 1490mm x 1300mm (103” x 58” x 51”) |

| Gross Weight | 1,250 kg / 2,755 lb |

| Material Construction | Food-grade stainless steel construction |

| Operating Environment | Indoor location, well ventilated room 15° C to 40° C (59° F to 104° F) Relative humidity 10% to 90% non-condensing environment |

| Installation | 1 Day |

| Noise | <60 dB |

| Manufactured | Italy |

| Life Expectancy | 20+ year major structural equipment |

| Warranty | 1 year OEM limited parts & labor |

Explore all our products

Ziel designs, builds and installs our processing lines with your requirements and product in mind. We will partner with you to design and build custom process systems that will best meet your goals.