Germany Cannabis Remediation,

Regulations + Market Updates

Germany’s adult-use market hit its one-year anniversary on April 1, 2025. As expected, the industry exploded over its first 365 days.

Both recreational and medical markets are seeing massive increases in consumer demand, which has led to a surge in imports from Canada, Portugal, the Netherlands, and other countries. Q4 2024 saw a rise in imports by 53% compared to Q3 2024 and 272% compared to Q4 2023. [1]

In 2025, Germany’s cannabis industry is expected to earn around €1 billion in revenue.[2]

Germany’s Current and Future Cannabis Supply

As its industry continues to boom, Germany will continue to import the majority of the cannabis products it sells.

When the CanG reform bill passed in April of 2024, it opened up domestic production within Germany. Previously, only three operations had been federally approved within the country’s borders. Still, it’s expected to take years for domestic production to be fully scaled and able to support German consumer demand. In the meantime, the country will maintain its reliance on imports from other countries.

Germany approaches its cannabis industry the same way it approaches pharmaceuticals, meaning anyone who wants to import to or produce within the country must meet strict regulatory requirements.

Germany Cannabis Remediation:

Exporting/Importing Requirements

Like any pharmaceutical product sold in Germany, cannabis manufacturers must earn an EU-GMP certification for their facilities.

The EU-GMP certification process reviews every part of production, from major components like the machinery used and the procedures followed, to smaller items like ensuring the proper signage has been placed around the facility. The goal of the EU-GMP certification is to guarantee that the process used to produce a particular product is repeatable and consistent, making the same product every time.

A major part of that review is microbial compliance, around which Germany has the strictest requirements in the world. Their laws address topics like:

- Cannabinoid Content: The total THC and CBD levels in a product must not deviate by more than ±10% from labeled values, ensuring consistency and consumer safety.

- Foreign Matter: The presence of seeds, insects, mold, or other contaminants is prohibited.

- Heavy Metals: There are specific limits for arsenic, cadmium, and lead, with stricter thresholds for inhaled products due to higher patient exposure risks.

- Loss on Drying: The maximum allowable moisture content is 12%.

They also require all cannabis flower to achieve the same approved microbial limits as is allowed for all Herbal Drugs under their Pharmaceutical Monograph. This requires operators to remediate their flower. [3]

Cannabis remediation falls into two categories: ionizing and non-ionizing. German regulators prefer non-ionizing technologies because they’re safer for the product and the consumer, and because of this, they entice operators to use them over ionizing options.

Germany Encourages Non-Ionizing Remediation for Cannabis

Ionizing radiation, such as gamma, e-beam, and X-ray technologies, alters the molecular structure of the plant. Operators who decontaminate their flower using these options must apply for an AMRadV license for every cannabis strain they treat before that strain can be sold in Germany. This process is costly (around €4,500 per license) and slow, often taking up to 12 months for approval.

In contrast, non-ionizing remediation methods like Radio Frequency (RF) do not require AMRadV licensing. Because non-ionizing technologies do not affect the molecular integrity of the plant, they’re considered a gentler, safer, and more regulatory-friendly option.

As Germany’s cannabis market scales, cultivators and importers are increasingly seeking non-ionizing cannabis remediation options to ensure faster compliance, reduce regulatory risk, and save money.

Ziel RFX: The Compliance Solution

for Germany Cannabis Remediation

Radio Frequency works by penetrating the cannabis flower with long, low-energy wavelengths. The vibration from these radio waves causes the water molecules inside the plant to vibrate in unison, generating enough heat to kill microbial pathogens without harming the plant’s chemical compounds.

Choosing non-ionizing technology like RF to achieve microbial compliance is the most cost-effective solution for those looking to export cannabis to Germany. The technology has already been approved for USDA Organic operations in other industries and is currently being used in EU-GMP certified cannabis productions in Europe, making it easy to incorporate it into facilities that are already EU-GMP certified or those that are looking to become certified.

Ziel’s RFX machine, the leading Radio Frequency decontamination solution, has the largest throughput of any microbial control solution on the market today, making it ideal for cultivators looking to process large volumes.

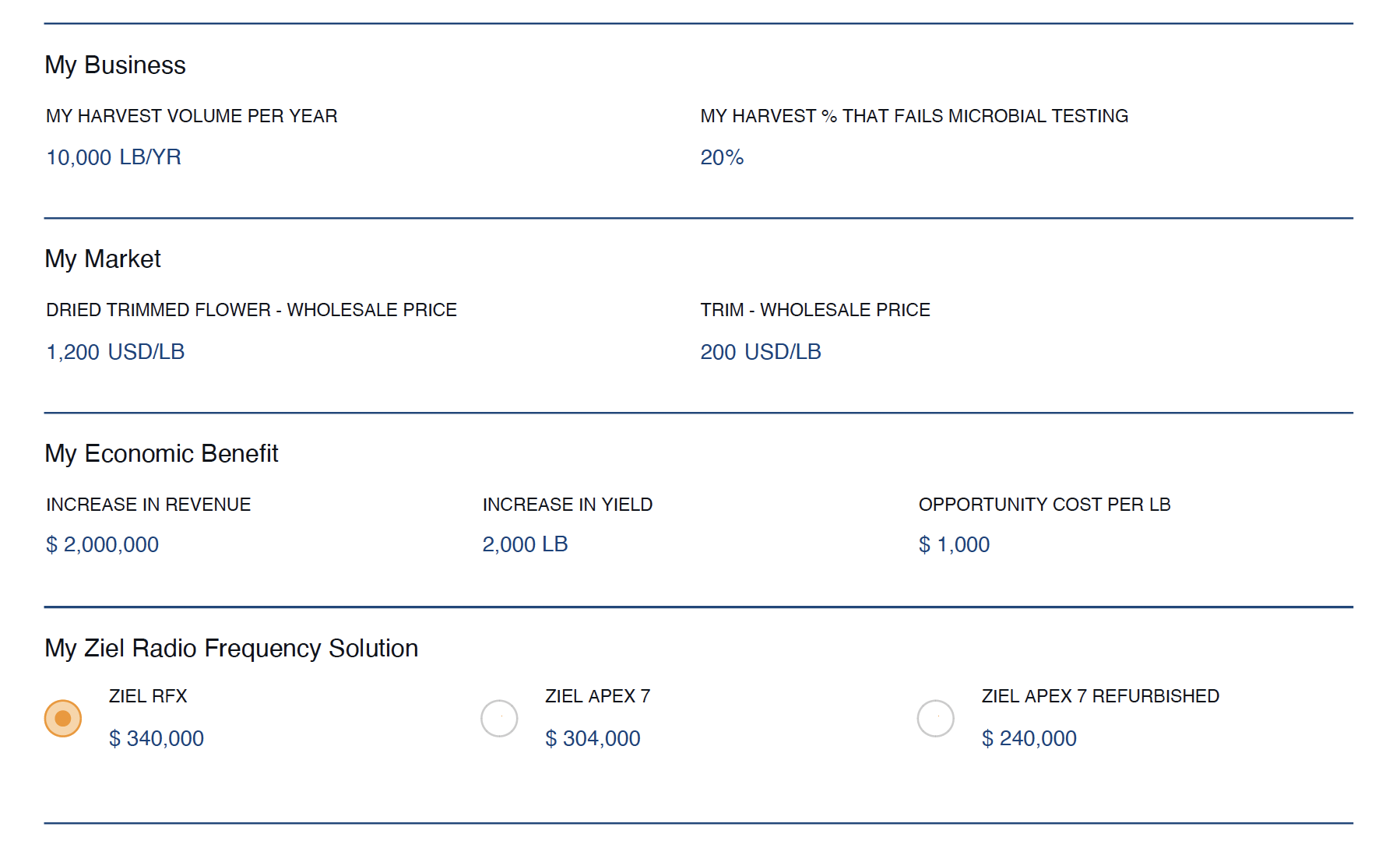

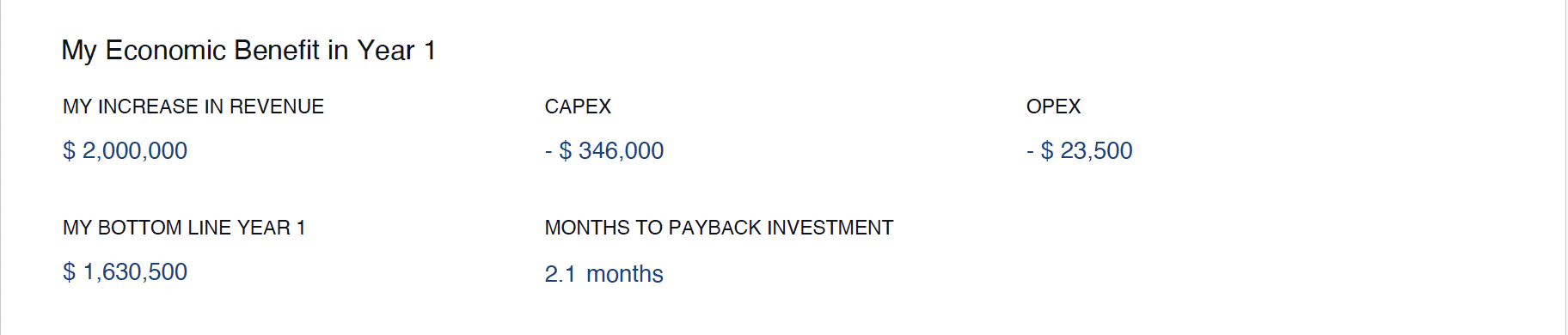

Using Ziel’s Business Case Calculator, cultivators can determine how much revenue the RFX will recover for their business by increasing harvest yields, avoiding compliance failure, and eliminating the need to send contaminated product off to extraction. This, in turn, also eliminates the subsequent costs for retesting. Cultivators interested in exporting to Germany are also encouraged to add up how much they’d spend in time and money on AMRadV licenses for each of their strains treated with ionizing radiation, an expense that’s nonexistent with Ziel’s RF technology.

Cost Savings of Radio Frequency

Cannabis Decontamination with Ziel

To better understand just how much money the RFX can save cannabis manufacturers, explore the example below.

Using a wholesale selling price of €4,000/kg, if a processor failed 20% of their annual harvest, they would be forced to retest, treat again, or offload the failed product to a manufacturer for a deep discount—as much as 90%, or €400. This snapshot shows the revenue a business will recover within the first year of using the RFX, based on recovering 20% of the harvest that fails microbial testing on 1,000 kgs of dry flower harvested annually.

In this example, more than €720,000 of revenue is recovered in the first year alone. That’s more than double the cost of the RFX.

The Future of Germany’s Cannabis Market

Cannabis cultivators looking to join Germany’s market must have a mold treatment solution in place. Radio Frequency is the safest and most cost-effective option on the market, requiring no additional licensing and operating in alignment with EU-GMP processing guidelines.

If you’re looking to streamline your product’s entry and position in the German cannabis market, let’s talk. Ziel’s RFX offers the largest throughput of any technology currently available and boasts a >99% pass rate for regulatory compliance. Together, we can get you set up to leverage what’s shaping up to be one of the largest cannabis markets in the world.