From Thailand to Colombia: Growers Are Ditching Portugal for On-Site GMP

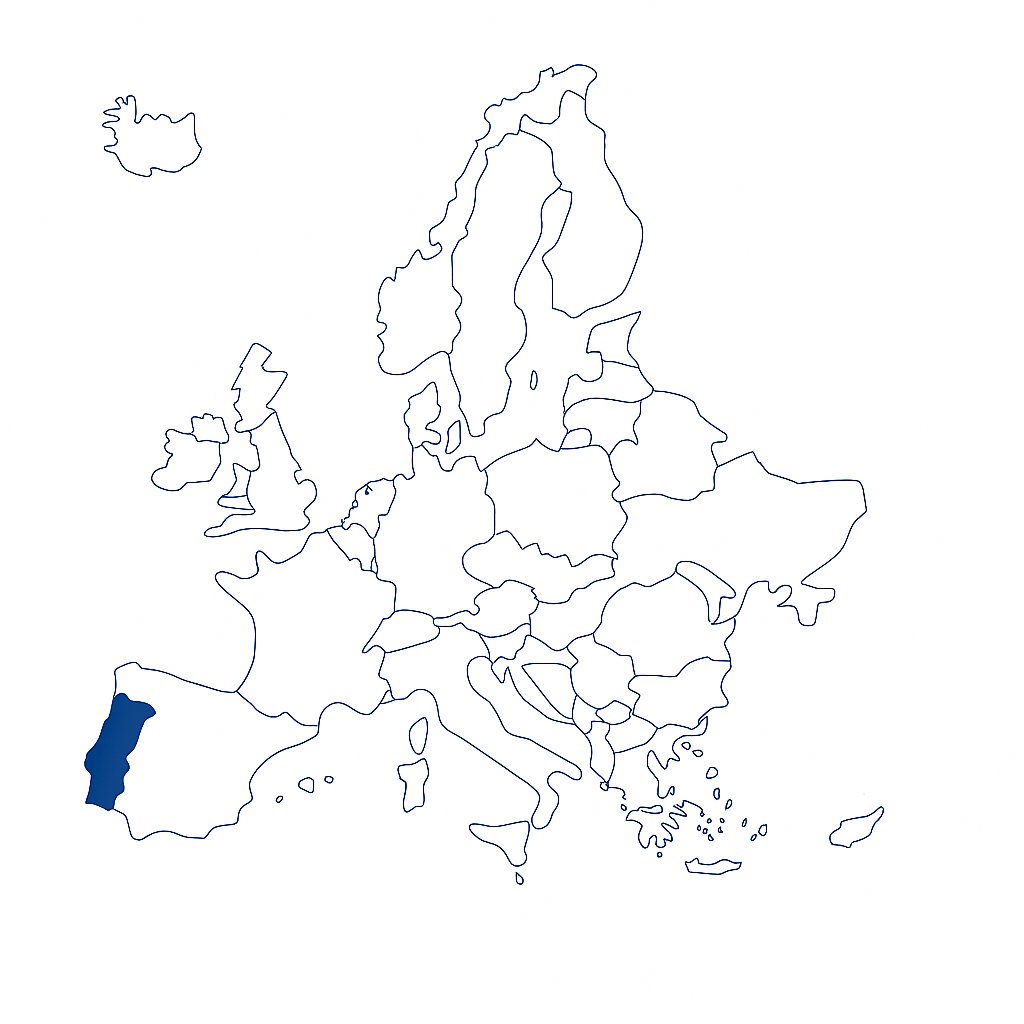

For years, Portugal has served as the go-to GMP Processor for cannabis cultivators around the world. With EU recognition, Infarmed oversight, and an established export framework, Portugal processes thousands of kilos of cannabis grown by GACP producers in countries like Canada, Colombia, and Thailand. These growers ship flower to Portugal for microbial remediation, GMP-compliant packaging, and final processing to access key European markets.

But this model is slow, expensive, and unsustainable.

Ziel’s Radio Frequency (RF) technology offers growers an alternative: in-country microbial remediation that meets EU standards without outsourcing. By keeping post-harvest processes at origin, cultivators can lower costs, speed up timelines, and gain full control over product quality

Why Portugal Became the GMP Processing Hub

- Progressive drug policy: In 2001, Portugal became the first country in the world to decriminalize all personal drug use, including cannabis.

- Legalization framework: Cannabis was legalized for regulated uses in 2018, with implementation guidelines finalized in 2019.

- First international export: Portugal’s first cannabis shipment took place in 2019, when 500 kilograms were exported by Tilray to Germany.

- Regulatory efficiency: Oversight by Infarmed encouraged foreign investment and positioned Portugal as an EU-compliant export hub.

Understanding the GACP-to-GMP Gap

GACP governs everything from seed propagation to harvest. It ensures plants are grown consistently, safely, and in line with WHO guidelines. But GACP only covers part of the chain to market.

GMP begins after harvest. It includes bucking, drying, trimming, microbial decontamination, testing, and final packaging. Without a local GMP-certified option, GACP growers must outsource their GMP processing, either in their own country or, more likely, an EU-based GMP Processor. This is why many producers in countries like Thailand and Colombia have relied on Portugal to meet the GMP processing required for exporting to the largest European markets, Germany and the UK. This system works, but adds significant cost and complexity for the producer and cuts into their profit margins.

Growers Are Shifting to In-Country GMP

Growers have built large-scale cultivation sectors around GACP compliance, which is essential for EU entry. Now, they’re also incorporating GMP compliance into their operations. Both Thailand and Colombia are strong examples of this shift to in-country GMP processing.

In Thailand, the evolving regulatory landscape supports a growing export sector. Producers are increasingly looking to build more control into their operations to leverage this and have started investing in GMP processing locally.

In Colombia, ideal growing conditions and a well-established GACP framework have positioned the country as a major flower supplier, and growers there are also starting to incorporate GMP locally.

The global trend is clear. Instead of relying on GMP Processors in Portugal, more growers are choosing to bring post-harvest compliance into their own facilities. Ziel makes this transition possible.

What Ziel RF Remediation Delivers

Ziel’s Radio Frequency (RF) remediation systems allow growers to meet strict EU microbial safety standards in-house. The technology uses non-ionizing energy to reduce total yeast and mold counts by more than 99.9 percent, without using ionizing radiation, gas, or chemicals.

Key Benefits of Ziel’s RF Technology Include:

- Meets EU Pharmacopeia Standards

- Avoids labeling and registration issues related to irradiation in Germany, like the AmRadV license

- Preserves terpenes, aroma, and cannabinoid profiles

- Compatible with organic certification

- Compact design with fast cycle times for high-throughput processing

- Commercially proven and validated under EU GMP standards

- Technology has been commercially used and validated in the food industry for over 20 years

GMP Processor vs In-Country Remediation

| Factor | GMP Processor (Portugal, Switzerland, Czech) | Ziel In-Country Remediation |

|---|---|---|

| Microbial Remediation | Outsourced, high service cost | On-site with low operating cost |

| Control Over Quality | Limited | Full internal oversight |

| Time to Market | Weeks | Days |

| Strain Integrity | May be lost during repackaging | Maintained throughout |

| Organic Compatibility | Variable | Consistently supported |

GACP and RF Reduce EU Entry Costs

Growers in Southeast Asia, Latin America, and other emerging markets already operate under GACP frameworks. These practices support quality and traceability through cultivation and harvest. But for European entry, post-harvest compliance is essential. By bringing remediation in-house, growers gain faster access to market, more consistent outcomes, and higher profitability.

Global Advantage with Local Control

Relying on Portugal as a GMP Processor may have worked in the early days, but it is no longer the best option. With rising demand and tighter margins, cultivators are building resilience into their operations by controlling every step of the process.

Thailand, Colombia, and other regions that are prime for growing quality cannabis are now leading this shift. These growers already meet GACP standards. With Ziel’s RF remediation technology, they are now able to meet post-harvest GMP requirements directly in-country.

This reduces reliance on overseas facilities, protects product quality, and puts more value back into the hands of the grower.

Key Takeaways

- Portugal is widely used as a GMP Processor, but this adds cost and delays

- Growers in Thailand, Colombia, and similar regions are now investing in GMP processing locally

- Ziel’s RF remediation technology provides in-house microbial control that meets EU requirements

- This approach gives growers control over quality, documentation, and timelines

- With in-country solutions, cultivators can reduce dependency, protect margins, and strengthen their export position

Ready to bring GMP compliance in-house?

Talk to Ziel about RF remediation solutions for your facility.