Cannabis Remediation in Colombia: Keeping Your Exports within Pharmacopoeia Scope

Colombia offers an ideal environment for large-scale outdoor cultivation. The country’s sunny climate and low farming costs are powerful advantages in the global cannabis market.

Colombia Cannabis History Highlights

- 2016: Colombia legalized medical cannabis and related products.

- 2022: New regulations allowed export of dried, high-THC flower.

- 2023: Medical cannabis exports reached $10.8 million.

- 2025: Nearly 20 multinational cannabis companies have invested in Colombia.

As exports increase, producers face the challenge of meeting strict quality standards abroad. At Ziel, we already support producers across Europe and North, Central, and South America, allowing us to bring our global expertise to ensure Colombian cultivators succeed. With the right technology and careful processing, Colombia has the potential to become a top global supplier.

Meeting Global Standards

The European Union’s 27 countries represent one of the largest potential markets, with more than 350 million people. Leveraging this market by exporting cannabis to the EU involves strict compliance with agricultural and manufacturing standards.

European regulators apply pharmaceutical-level standards to their cannabis market, which set tight limits on yeast, mold, and bacteria. In practice, every crop must pass strict safety tests before it can reach patients. Producers have to maintain very low microbial counts and adhere to the EU’s Good Agricultural and Collecting Practices (GACP) and Good Manufacturing Practices (GMP), as well as to individual country requirements. For example, in Germany, each cannabis strain treated by ionizing radiation requires a separate registration, a costly obstacle our Radio Frequency (RF) approach avoids.

The EU does not have a single cannabis monograph, so growers must adapt broad pharma microbiology requirements. Colombian producers planning to enter the EU market need to build these requirements into their operations from the beginning, including thorough testing and reliable records.

Microbes: A Hidden Risk

Mold, yeast, and other pathogens are serious risks in cannabis production, especially in warm and humid climates like Colombia’s. The same conditions that support strong plant growth also encourage mold. Mold can develop during drying or storage, and even properly dried flower can become contaminated if humidity changes.

Regulators test for total yeast and mold (TYMC), total bacteria (TAMC), and pathogens such as Aspergillus or Salmonella. If a batch exceeds limits, it must be reworked or destroyed, which cuts into profits. Contaminated cannabis might have to be converted into extract products, which usually hold less value. We’ve seen many producers forced to shift product to lower-value extracts, a result that effective remediation can help avoid.

Radio Frequency Remediation

Ziel uses Radio Frequency technology to support safe and effective cannabis remediation. RF energy is non-ionizing, which means it does not change the chemical structure of the plant. Instead, RF waves oscillate water molecules within the flower, creating volumetric heating that kills mold and bacteria while maintaining product quality. Our RF system can reduce yeast and mold counts by over 99.9%, allowing producers to save harvests and avoid major losses. Unlike traditional, ionizing methods like X-ray or E-Beam, RF treatment is non-ionizing and does not require special labeling or licensing.

Safe, Organic Treatment

We are committed to providing a safe and organic process. Ziel’s machines require only a food-grade nylon bag and minimal electricity per cycle, producing no chemical residues or impact on the plant’s sensory qualities. The RFX and APEX 7 can run continuously with no required downtime, making them practical solutions for high-volume producers.

Fast Implementation

Our RFX system is designed for speed and efficiency. It can handle hundreds of pounds of flower daily and operate with 99.9% uptime. We help clients install and start using the system in just a few days, providing on-site training and process support to help teams learn quickly. The machine runs on standard single-phase power, so most facilities do not need costly upgrades. With common power and intuitive software, the RFX fits easily into existing production lines. This means Colombian producers can start remediation right away and protect harvests that could otherwise be at risk.

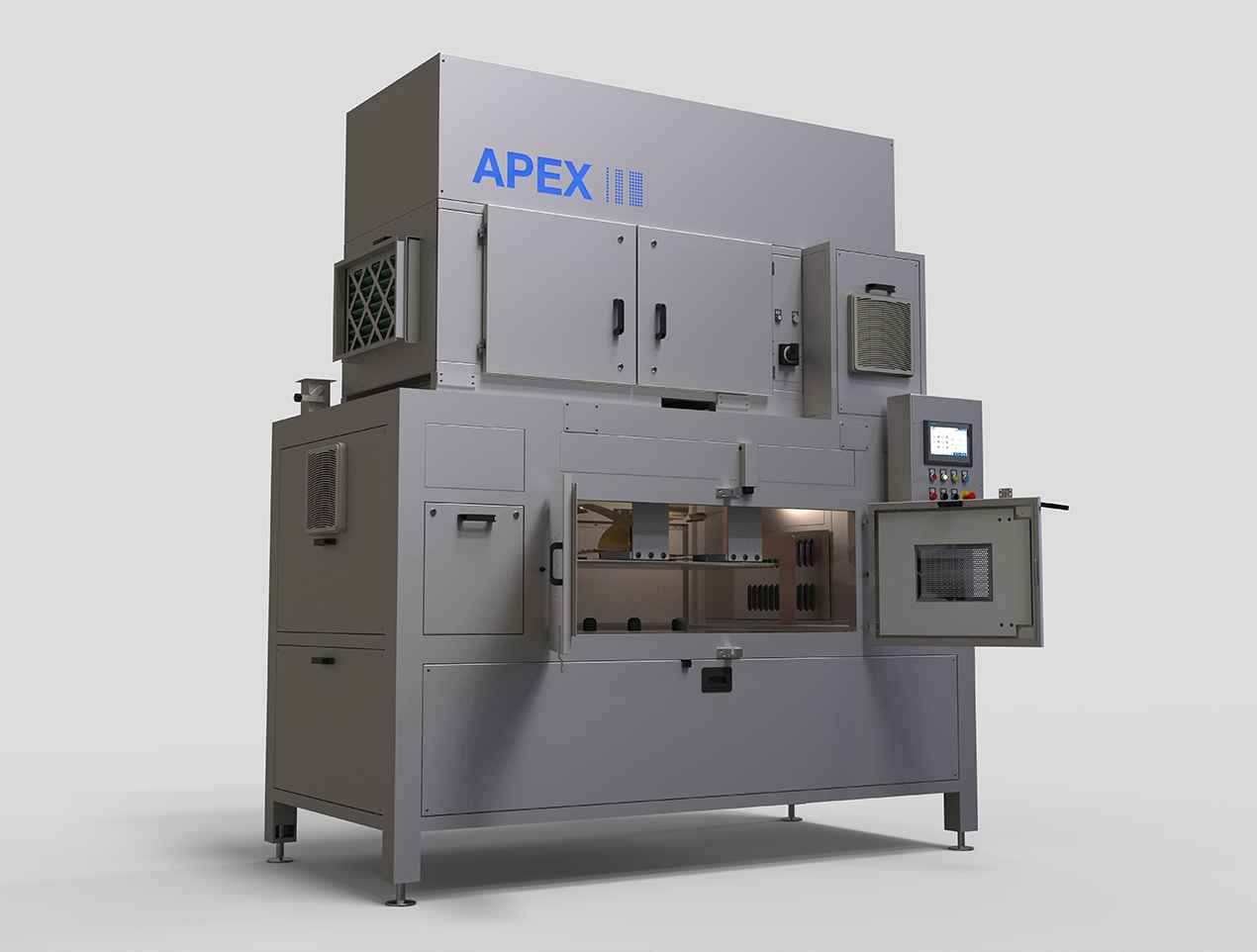

For those with three-phase power and more space, we have our APEX 7 units which have the same throughput and efficacy.

Both solutions can get cultivators up and running quickly, as Ziel often carries inventory in stock.

Protecting Profits and Patients

At Ziel, we believe cannabis remediation is essential for Colombian producers looking to succeed in export markets. By adding a reliable microbial control step, growers can protect both patient safety and business profits. Clean, safe products help build trust with regulators and international buyers, strengthening Colombia’s position as a trusted global supplier. With our Radio Frequency solutions, producers can confidently meet the strictest standards and keep their brands strong in competitive markets.

Key Takeaways

- Colombia’s warm climate and low farming costs give it strong advantages in the global cannabis market.

- Producers must meet strict EU standards for microbial safety, including GACP and GMP compliance.

- Mold and microbial contamination pose major risks, especially in humid climates.

- Ziel’s Radio Frequency (RF) remediation reduces microbes by over 99.9% without affecting potency or requiring chemical treatments.

- RF treatment supports organic certification and keeps flower natural, aromatic, and potent.

- Fast implementation and high throughput make RF a practical solution for large-scale operations.

- Reliable remediation can help protect patient safety, avoid profit loss, and strengthen Colombia’s reputation as a global cannabis supplier.