How Cultivation Practices, Manufacturing Standards, and the Pharmacopoeia Shape Cannabis Quality in Germany

Cannabis quality in Germany is guaranteed by three standards: Good Agricultural and Collection Practice (GACP), Good Manufacturing Practice (GMP), and the European Pharmacopoeia. GACP governs how cannabis is grown and harvested, GMP regulates processing and packaging after harvest, and the Pharmacopoeia defines the final specifications for potency, purity, and appearance. Together, these rules create full traceability and ensure that every batch reaching pharmacies is consistent, safe, and compliant.

Medical cannabis in Germany is regulated as carefully as any other medicine. Every batch that reaches a pharmacy must pass through a system designed to protect patients. At Ziel, we support producers navigating this system with our remediation solutions.

Three main elements work together to safeguard quality and build patient trust:

- Good Agricultural and Collection Practice (GACP): rules for how cannabis is grown and harvested

- Good Manufacturing Practice (GMP): rules for how cannabis is processed, packaged, and tested

- European Pharmacopoeia Cannabis Flower Monograph: the final checklist every batch must meet before release

Understanding how these three elements connect helps producers stay compliant and gives patients peace of mind.

What Is Good Agricultural and Collection Practice (GACP)?

GACP sets the foundation for cannabis quality by defining cultivation and harvest standards.

- Avoiding contamination: Farmers must monitor soil, water, and nutrients to keep out pesticides, mold, and heavy metals.

- Consistency across crops: Standardized methods produce flowers with predictable cannabinoid and terpene levels. This is essential for doctors prescribing cannabis as medicine.

- Traceability from seed to harvest: Every plant is documented, creating a verifiable history for inspectors.

- Imports must comply too: Since Germany imports much of its cannabis, all imported cannabis must also be grown in GACP-compliant facilities.

What's changing: In August 2025, the EMA formally adopted Revision 1 of its GACP (Good Agricultural and Collection Practice) guideline — the first update since 2006. The revision strengthens requirements for documentation, clarifies roles and responsibilities across the supply chain, and tightens alignment with GMP-level precision. For growers and collectors, it means more extensive batch records, process controls, equipment qualification, and daily monitoring of critical parameters (especially in indoor cultivation). For patients and consumers, it aims to ensure greater consistency, safety, and quality of herbal starting materials. Read the guidelines here.

What Is Good Manufacturing Practice (GMP)?

Once harvested, cannabis must be treated like a pharmaceutical product. GMP governs post-harvest handling.

- Controlled spaces: Processing areas must be clean and tightly monitored to prevent contamination.

- Documented procedures: Every step, from drying times to packaging, must be written, followed, and reviewed.

- Quality management: Processes must be validated, deviations logged, and performance reviewed over time.

- Safe distribution: Good Distribution Practice extends protections into storage and transport, ensuring cannabis remains stable until it reaches pharmacies.

Without GMP certification, cannabis cannot be sold in Germany's medical market.

What Is the Role of European Pharmacopoeia?

The European Pharmacopoeia (Ph. Eur.) serves as the official rulebook for medicines across Europe. Its Cannabis Flower Monograph sets the final product requirements.

- Potency standards: THC and CBD content must be within 10 percent of the labeled value.

- Purity requirements: Strict limits apply for heavy metals, and low moisture levels reduce mold risk.

- Physical appearance: Flowers must be free of seeds and large leaves, with only minimal foreign matter allowed.

Harmonized rules across Europe: Shared standards smooth the flow of imports and exports and give patients consistent quality across the EU.

How GACP, GMP, and the Pharmacopoeia Work Together

Think of these standards as a three-step safety net:

- GACP: Defines how the plant is grown and harvested.

- GMP: Regulates processing, testing, and packaging.

- Ph. Eur.: Confirms the finished product before it reaches pharmacies.

Together, they create full traceability. If an issue arises, regulators can track a product back to the exact harvest and facility.

What It Means for Producers and Patients

- For producers: Compliance requires investment in facilities, training, and documentation. But meeting these standards is the only way into Germany’s medical cannabis market, and it demonstrates pharmaceutical-level credibility.

- For patients: These safeguards build trust. Prescribed cannabis is held to the same standards as other medicines on the pharmacy shelf.

Ziel's Role in Supporting Compliance

At Ziel, we work with licensed producers and processors who face these requirements. Our support includes:

- Microbial Remediation Solutions

- EU GMP Validation support through IQ OQ PQ Documentation

- Monitoring customer success with Monthly meetings

Our goal is to make compliance practical and achievable, without sacrificing flower quality.

Final Takeaway

Germany shows how medical cannabis can be fully integrated into a pharmaceutical system. Cultivation rules protect the plant, GMP ensures safe handling, and the European Pharmacopoeia defines the final product patients receive.

- For producers: Staying ready means up-to-date records, validated processes, and responsive quality systems.

- For patients: Every prescription carries the assurance that cannabis has passed through the same strict checks.

Ziel helps producers move through this pathway with clarity, efficiency, and a focus on both compliance and product integrity.

Europe's Cannabis Boom by the Numbers and Why Ziel Keeps It Safe

The European cannabis market is entering a period of explosive growth. Billions of euros are flowing into medical programs, cultivation hubs are scaling exports, and pilot legalization projects are underway. Yet behind the headlines and the numbers, one question remains central: how do we keep cannabis safe, compliant, and ready for international export?

That is where Ziel comes in. With advanced radio frequency decontamination technology, Ziel ensures that cannabis producers across Europe can meet EU-GMP standards, meet regulatory compliance, and preserve product quality while the market surges ahead.

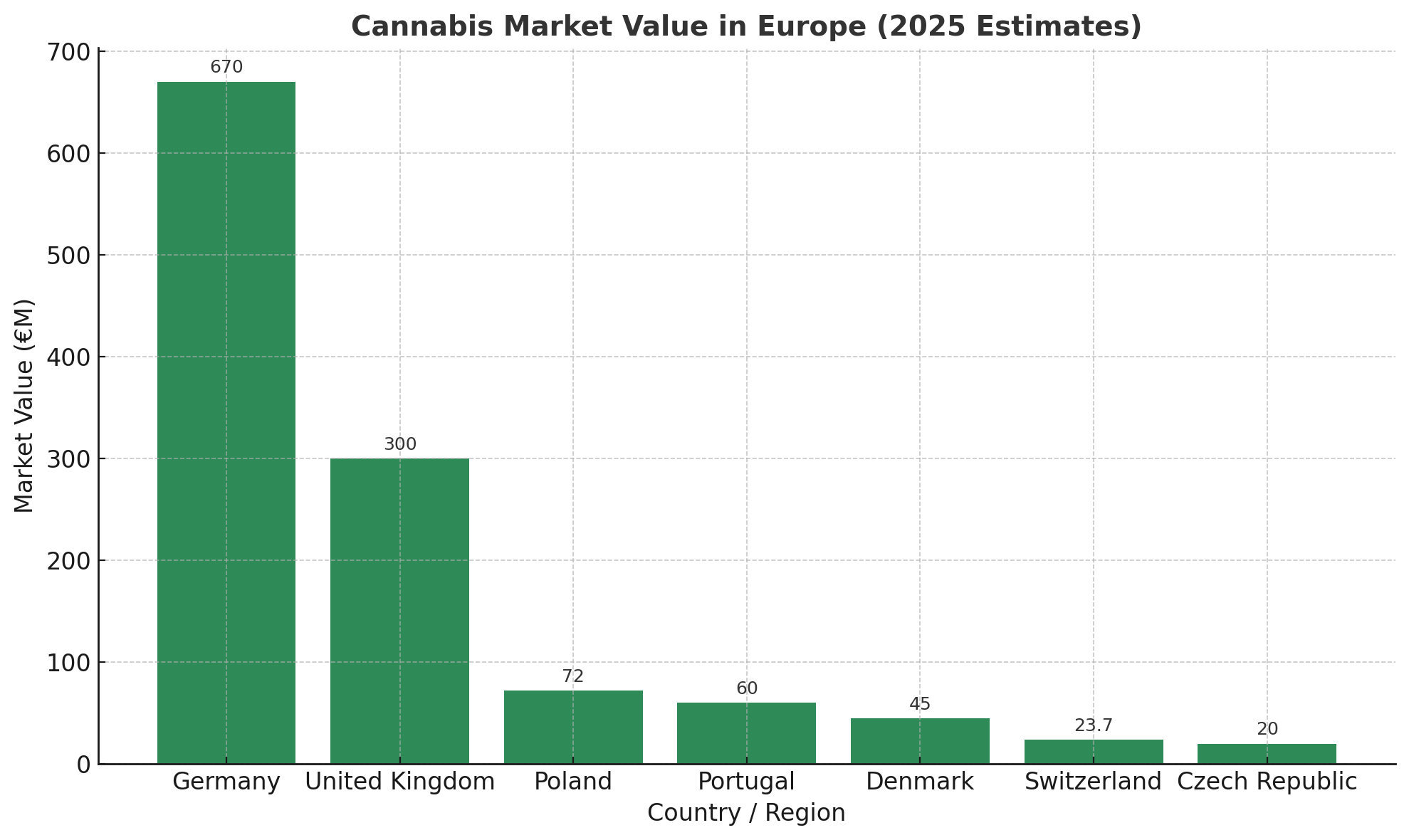

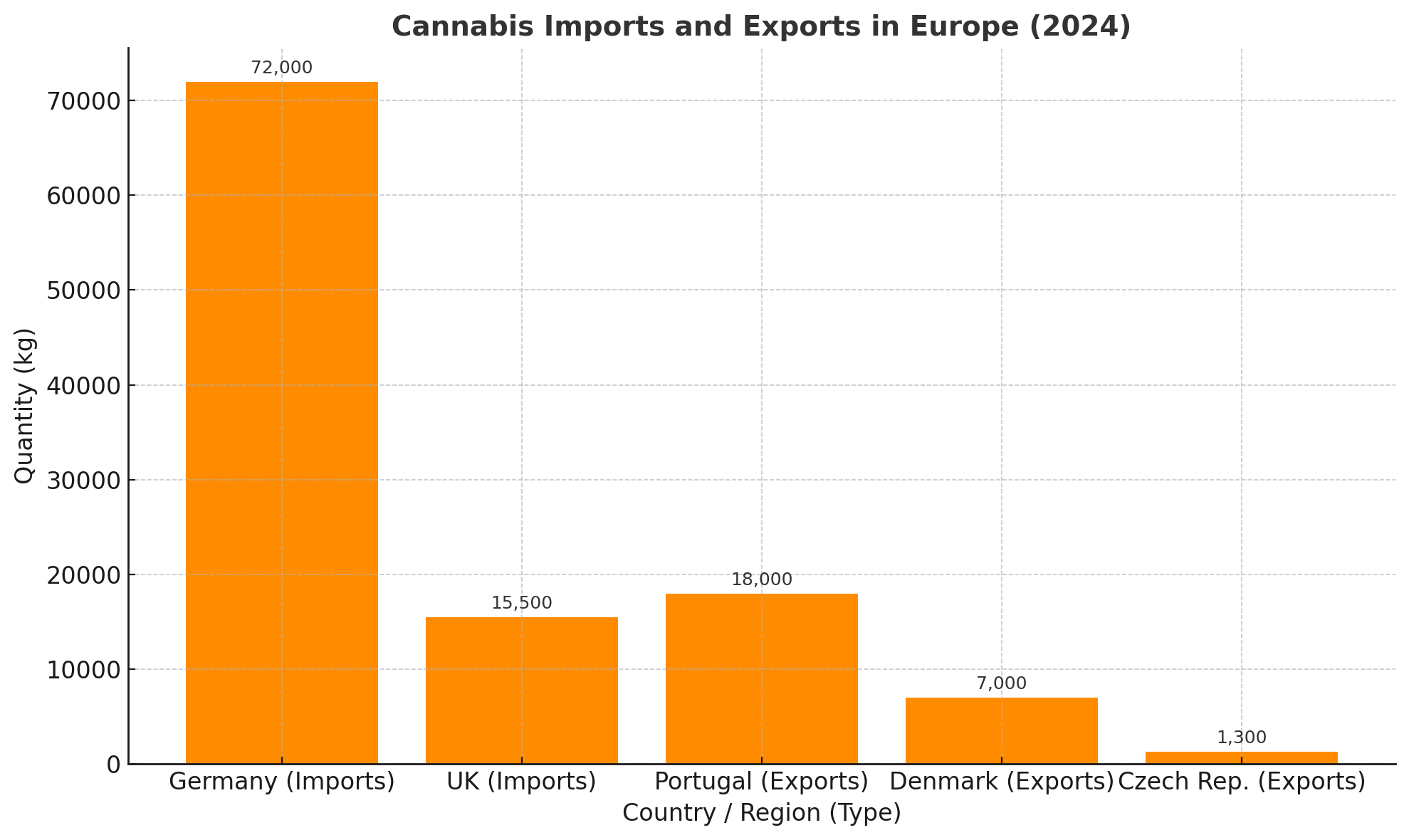

The table below breaks down the numbers shaping Europe's cannabis industry in 2025, based on reporting from MMJ Daily.

Cannabis in Europe by the Numbers (2025 Estimates)

| Country / Region | 2025 Market Value | 2024 Exports / Imports | Exports To |

|---|---|---|---|

| Germany | €670M | Imports: 72,000 kg | — |

| United Kingdom | €300M | Imports: 15,500 kg | — |

| Poland | €72M | — | — |

| Portugal | ~€60M | Exports: 18,000+ kg | Germany (50%), Spain, Poland, UK, Australia |

| Denmark | ~€45M | Exports: 7,000 kg | Germany |

| Switzerland | €23.7M (pilots) | — | — |

| Czech Republic | €20M | Exports: 1,300 kg | Germany |

What the Numbers Show

- Germany dominates as Europe’s largest medical cannabis market, with imports doubling in 2024.

- The UK continues rapid growth, supported by telehealth adoption and domestic cultivation.

- Poland, Portugal, and Denmark are smaller but strategically vital markets, supplying Germany and other EU states.

- Switzerland is pioneering adult-use pilots, already recording €23.7 million in sales.

- The Czech Republic has begun to scale exports, signaling its intent to grow as a supplier.

This growth represents more than opportunity. As volumes expand, the risks of contamination, recalls, and compliance failures also grow.

Ziel: Setting the Remediation Standard

Ziel's role in Europe's cannabis future is clear:

- Safety at scale: Eliminating harmful microbes without damaging cannabinoids or terpenes.

- Compliance made simple: Meet Pharmacopeia standards with flexible recipe settings

- Value protection: Preserving flower quality in markets where price competition is intensifying.

- Cross-border confidence: Giving regulators and importers assurance that products meet the highest quality standards, without having to register strains with AmRadV in Germany.

As Europe's cannabis market races toward multi-billion-euro growth, Ziel ensures the foundation is strong, safe, and scalable. Without it, the numbers are just numbers. With Ziel, they become a roadmap to a secure and thriving industry.

11 Ways to Maximize Cannabis Profits

in Thailand

Thailand’s cannabis sector combines year-round production, low-cost labor, an experienced pharmaceutical industry, high-grade indoor flower, and strategic export potential with strong domestic demand and political support.

For established operators supplying GMP-certified markets in Europe, or eyeing both export and local channels, these strategies can significantly increase margins and drive revenue.

Leverage Year-Round Harvests for Consistent Revenue

Multiple harvests per year keep your cash flow steady, facilities fully utilized, staff employed, and a steady supply chain for importers.

Profit impact: Adding two extra harvest cycles annually could mean €1–1.5M in additional revenue without increasing fixed infrastructure costs.

Reduce Overhead with Thailand’s Cost Base

Labor is the single biggest cost input for growing cannabis. Thailand’s low labor costs, along with lower land, and utilities (electric), drive down the cost per gram. This lets you undercut high-cost competitors and retain healthy gross margins.

Profit impact: Producing at €0.60/gram instead of €1.20/gram doubles gross margin before logistics and compliance costs

Use Skilled Labor to Improve Quality and Reduce Profit Loss

Thailand’s experienced pharmaceutical and farm workforce reduces overall labor costs, the single biggest cost component facing cultivators. And an experienced and hard working labor force reduces errors and increases productivity. It is not a surprise that the largest MSO uses a Thai workforce in its Portugal facility.

Profit impact: Preventing a 5% yield loss on a 500kg crop preserves €50,000 in potential revenue.

Align with GACP Standards from the Start

Integrating Good Agricultural and Collection Practices early avoids expensive retrofits and compliance delays.

Profit impact: Avoiding one failed compliance audit can save €30,000–€50,000 in freight, testing, and rework costs.

Leverage Government Support and First-Mover Advantage

Thailand has shifted cannabis into a tightly regulated medical-only framework. While this has slowed recreational activity, it signals the government’s intent to create a controlled, pharmaceutical-grade supply chain.

Operators who move early into compliance with GACP and GMP standards face fewer competitors and gain licensing advantages.

Profit impact: Political alignment reduces risk of costly regulatory setbacks and supports faster licensing approvals.

Shorten Time to Market with Direct Shipping Routes

Proximity to major air and sea freight hubs ensures rapid delivery to EU GMP processors, preserving potency and product quality.

Profit impact: Maintaining top-grade quality can protect €1–€2 per gram in premium pricing.

Keep Organic Certification for Price Premiums

Avoid gamma or X-ray treatments that remove organic eligibility and require extra labeling. Ziel’s Radio Frequency remediation meets microbial safety standards without ionizing radiation.

Profit impact: Organic-certified cannabis can sell for 15–25% more, worth €150,000–€250,000 annually on 1 tonne of exports.

Maintain Export Volumes by Eliminating Microbial Failures

One failed microbial test can turn premium flower into low-margin extract material. In-house remediation ensures compliance every time.

Profit impact: Saving a single 200kg batch from downgrade preserves €600,000+ in potential revenue.

Capitalize on Domestic Demand and Cannabis Tourism

With over 12,000 licensed dispensaries and thriving cannabis tourism hubs like Bangkok, Phuket, and Pattaya, the local market offers immediate sales channels.

Profit impact: Selling surplus locally at retail margins can yield higher per-gram profits than wholesale exports, especially during tourism peaks.

Expand Into Emerging Asian Markets

Thailand’s location allows cost-effective distribution to future medical cannabis markets in Asia. Diversifying channels protects against EU price fluctuations.

Profit impact: Selling in multiple regions reduces reliance on a single buyer base and prevents inventory stagnation.

Replace Brokers with In-House Remediation to Capture Margin

Thailand’s domestic market has transitioned into a prescription-based medical system. While this has reduced casual retail demand, it has created regulated distribution through clinics and pharmacies.

Profit impact: Selling surplus locally into medical channels can provide higher per-gram returns than bulk exports, especially for operators who achieve organic certification and GMP compliance.

Profit impact: Instead of paying a broker or GMP washer in Europe to “clean” your flower, install Ziel’s RF remediation system on-site. This approach cuts costs, avoids delays, and preserves quality.

Case Study: Broker vs In-House Ziel Remediation

| Factor | Broker/GMP Washer (Portugal) | In-House Ziel RF |

|---|---|---|

| Broker fee | €0.50–€0.70/gram | €0 |

| Remediation fee | €0.50–€0.80/gram | €0.05–€0.10/gram |

| Total per gram | €1.05–€1.60 | €0 |

| Annual cost on 1 tonne | €1.05M–€1.6M | €50K–€100K |

Annual Savings: €950,000–€1,550,000

Throughput: 73 kg per 8-hour shift (~€10 electricity cost)

ROI: Pays for itself in 2–3 months

Extra Advantages:

- Faster turnaround — no broker queues

- Avoids AMRadV licensing fees and months-long delays for strain approvals in Germany

- No Radura labeling for irradiated product or loss of organic status

- Preserves cannabinoids, terpenes, and visual quality

- Full control over compliance documentation and chain of custody

Final Thoughts

By combining Thailand’s year-round cultivation potential, low-cost structure, domestic and export markets, and advanced in-house quality control, cannabis operators can build highly profitable, resilient supply chains. For those targeting the EU, in-house RF remediation from Ziel removes one of the largest hidden costs in the process, ensuring that more of your harvest’s value stays where it belongs: in your business.

From Thailand to Colombia: Growers Are Ditching Portugal for On-Site GMP

For years, Portugal has served as the go-to GMP Processor for cannabis cultivators around the world. With EU recognition, Infarmed oversight, and an established export framework, Portugal processes thousands of kilos of cannabis grown by GACP producers in countries like Canada, Colombia, and Thailand. These growers ship flower to Portugal for microbial remediation, GMP-compliant packaging, and final processing to access key European markets.

But this model is slow, expensive, and unsustainable.

Ziel’s Radio Frequency (RF) technology offers growers an alternative: in-country microbial remediation that meets EU standards without outsourcing. By keeping post-harvest processes at origin, cultivators can lower costs, speed up timelines, and gain full control over product quality

Why Portugal Became the GMP Processing Hub

- Progressive drug policy: In 2001, Portugal became the first country in the world to decriminalize all personal drug use, including cannabis.

- Legalization framework: Cannabis was legalized for regulated uses in 2018, with implementation guidelines finalized in 2019.

- First international export: Portugal’s first cannabis shipment took place in 2019, when 500 kilograms were exported by Tilray to Germany.

- Regulatory efficiency: Oversight by Infarmed encouraged foreign investment and positioned Portugal as an EU-compliant export hub.

Understanding the GACP-to-GMP Gap

GACP governs everything from seed propagation to harvest. It ensures plants are grown consistently, safely, and in line with WHO guidelines. But GACP only covers part of the chain to market.

GMP begins after harvest. It includes bucking, drying, trimming, microbial decontamination, testing, and final packaging. Without a local GMP-certified option, GACP growers must outsource their GMP processing, either in their own country or, more likely, an EU-based GMP Processor. This is why many producers in countries like Thailand and Colombia have relied on Portugal to meet the GMP processing required for exporting to the largest European markets, Germany and the UK. This system works, but adds significant cost and complexity for the producer and cuts into their profit margins.

Growers Are Shifting to In-Country GMP

Growers have built large-scale cultivation sectors around GACP compliance, which is essential for EU entry. Now, they’re also incorporating GMP compliance into their operations. Both Thailand and Colombia are strong examples of this shift to in-country GMP processing.

In Thailand, the evolving regulatory landscape supports a growing export sector. Producers are increasingly looking to build more control into their operations to leverage this and have started investing in GMP processing locally.

In Colombia, ideal growing conditions and a well-established GACP framework have positioned the country as a major flower supplier, and growers there are also starting to incorporate GMP locally.

The global trend is clear. Instead of relying on GMP Processors in Portugal, more growers are choosing to bring post-harvest compliance into their own facilities. Ziel makes this transition possible.

What Ziel RF Remediation Delivers

Ziel’s Radio Frequency (RF) remediation systems allow growers to meet strict EU microbial safety standards in-house. The technology uses non-ionizing energy to reduce total yeast and mold counts by more than 99.9 percent, without using ionizing radiation, gas, or chemicals.

Key Benefits of Ziel’s RF Technology Include:

- Meets EU Pharmacopeia Standards

- Avoids labeling and registration issues related to irradiation in Germany, like the AmRadV license

- Preserves terpenes, aroma, and cannabinoid profiles

- Compatible with organic certification

- Compact design with fast cycle times for high-throughput processing

- Commercially proven and validated under EU GMP standards

- Technology has been commercially used and validated in the food industry for over 20 years

GMP Processor vs In-Country Remediation

| Factor | GMP Processor (Portugal, Switzerland, Czech) | Ziel In-Country Remediation |

|---|---|---|

| Microbial Remediation | Outsourced, high service cost | On-site with low operating cost |

| Control Over Quality | Limited | Full internal oversight |

| Time to Market | Weeks | Days |

| Strain Integrity | May be lost during repackaging | Maintained throughout |

| Organic Compatibility | Variable | Consistently supported |

GACP and RF Reduce EU Entry Costs

Growers in Southeast Asia, Latin America, and other emerging markets already operate under GACP frameworks. These practices support quality and traceability through cultivation and harvest. But for European entry, post-harvest compliance is essential. By bringing remediation in-house, growers gain faster access to market, more consistent outcomes, and higher profitability.

Global Advantage with Local Control

Relying on Portugal as a GMP Processor may have worked in the early days, but it is no longer the best option. With rising demand and tighter margins, cultivators are building resilience into their operations by controlling every step of the process.

Thailand, Colombia, and other regions that are prime for growing quality cannabis are now leading this shift. These growers already meet GACP standards. With Ziel’s RF remediation technology, they are now able to meet post-harvest GMP requirements directly in-country.

This reduces reliance on overseas facilities, protects product quality, and puts more value back into the hands of the grower.

Key Takeaways

- Portugal is widely used as a GMP Processor, but this adds cost and delays

- Growers in Thailand, Colombia, and similar regions are now investing in GMP processing locally

- Ziel’s RF remediation technology provides in-house microbial control that meets EU requirements

- This approach gives growers control over quality, documentation, and timelines

- With in-country solutions, cultivators can reduce dependency, protect margins, and strengthen their export position

Ready to bring GMP compliance in-house?

Talk to Ziel about RF remediation solutions for your facility.

Cannabis Remediation in Colombia: Keeping Your Exports within Pharmacopoeia Scope

Colombia offers an ideal environment for large-scale outdoor cultivation. The country’s sunny climate and low farming costs are powerful advantages in the global cannabis market.

Colombia Cannabis History Highlights

- 2016: Colombia legalized medical cannabis and related products.

- 2022: New regulations allowed export of dried, high-THC flower.

- 2023: Medical cannabis exports reached $10.8 million.

- 2025: Nearly 20 multinational cannabis companies have invested in Colombia.

As exports increase, producers face the challenge of meeting strict quality standards abroad. At Ziel, we already support producers across Europe and North, Central, and South America, allowing us to bring our global expertise to ensure Colombian cultivators succeed. With the right technology and careful processing, Colombia has the potential to become a top global supplier.

Meeting Global Standards

The European Union’s 27 countries represent one of the largest potential markets, with more than 350 million people. Leveraging this market by exporting cannabis to the EU involves strict compliance with agricultural and manufacturing standards.

European regulators apply pharmaceutical-level standards to their cannabis market, which set tight limits on yeast, mold, and bacteria. In practice, every crop must pass strict safety tests before it can reach patients. Producers have to maintain very low microbial counts and adhere to the EU’s Good Agricultural and Collecting Practices (GACP) and Good Manufacturing Practices (GMP), as well as to individual country requirements. For example, in Germany, each cannabis strain treated by ionizing radiation requires a separate registration, a costly obstacle our Radio Frequency (RF) approach avoids.

The EU does not have a single cannabis monograph, so growers must adapt broad pharma microbiology requirements. Colombian producers planning to enter the EU market need to build these requirements into their operations from the beginning, including thorough testing and reliable records.

Microbes: A Hidden Risk

Mold, yeast, and other pathogens are serious risks in cannabis production, especially in warm and humid climates like Colombia’s. The same conditions that support strong plant growth also encourage mold. Mold can develop during drying or storage, and even properly dried flower can become contaminated if humidity changes.

Regulators test for total yeast and mold (TYMC), total bacteria (TAMC), and pathogens such as Aspergillus or Salmonella. If a batch exceeds limits, it must be reworked or destroyed, which cuts into profits. Contaminated cannabis might have to be converted into extract products, which usually hold less value. We’ve seen many producers forced to shift product to lower-value extracts, a result that effective remediation can help avoid.

Radio Frequency Remediation

Ziel uses Radio Frequency technology to support safe and effective cannabis remediation. RF energy is non-ionizing, which means it does not change the chemical structure of the plant. Instead, RF waves oscillate water molecules within the flower, creating volumetric heating that kills mold and bacteria while maintaining product quality. Our RF system can reduce yeast and mold counts by over 99.9%, allowing producers to save harvests and avoid major losses. Unlike traditional, ionizing methods like X-ray or E-Beam, RF treatment is non-ionizing and does not require special labeling or licensing.

Safe, Organic Treatment

We are committed to providing a safe and organic process. Ziel’s machines require only a food-grade nylon bag and minimal electricity per cycle, producing no chemical residues or impact on the plant’s sensory qualities. The RFX and APEX 7 can run continuously with no required downtime, making them practical solutions for high-volume producers.

Fast Implementation

Our RFX system is designed for speed and efficiency. It can handle hundreds of pounds of flower daily and operate with 99.9% uptime. We help clients install and start using the system in just a few days, providing on-site training and process support to help teams learn quickly. The machine runs on standard single-phase power, so most facilities do not need costly upgrades. With common power and intuitive software, the RFX fits easily into existing production lines. This means Colombian producers can start remediation right away and protect harvests that could otherwise be at risk.

For those with three-phase power and more space, we have our APEX 7 units which have the same throughput and efficacy.

Both solutions can get cultivators up and running quickly, as Ziel often carries inventory in stock.

Protecting Profits and Patients

At Ziel, we believe cannabis remediation is essential for Colombian producers looking to succeed in export markets. By adding a reliable microbial control step, growers can protect both patient safety and business profits. Clean, safe products help build trust with regulators and international buyers, strengthening Colombia’s position as a trusted global supplier. With our Radio Frequency solutions, producers can confidently meet the strictest standards and keep their brands strong in competitive markets.

Key Takeaways

- Colombia’s warm climate and low farming costs give it strong advantages in the global cannabis market.

- Producers must meet strict EU standards for microbial safety, including GACP and GMP compliance.

- Mold and microbial contamination pose major risks, especially in humid climates.

- Ziel’s Radio Frequency (RF) remediation reduces microbes by over 99.9% without affecting potency or requiring chemical treatments.

- RF treatment supports organic certification and keeps flower natural, aromatic, and potent.

- Fast implementation and high throughput make RF a practical solution for large-scale operations.

- Reliable remediation can help protect patient safety, avoid profit loss, and strengthen Colombia’s reputation as a global cannabis supplier.

Colombia’s GACP Cultivators Move Swiftly Toward EU GMP

Colombia’s rich soils, year-round sunlight, and diverse microclimates make it an ideal place for cannabis cultivation. Over the past decade, supportive regulations and foreign investment have helped the country emerge as a key source of medical cannabis for global markets.

A major factor behind this growth has been cultivators’ adherence to Good Agricultural and Collection Practices (GACP). Certification under GACP confirms that cultivation, harvesting, and initial processing meet strict quality and safety standards set by the World Health Organization. For cultivators targeting Europe, GACP certification is not optional; it’s a requirement.

Leaving GMP Washers Behind: Colombia’s Shift to In-Country GMP

Despite this strong foundation, Colombian producers historically lacked EU Good Manufacturing Practice (GMP) certified processing facilities. While GACP (Good Agricultural and Collection Practices) governs how cannabis is cultivated and harvested, GMP focuses on what happens after, such as covering manufacturing, extraction, and packaging processes to ensure medical-grade safety, consistency, and quality control required for European markets. Without GMP-certified local processing, cultivators relied on European “GMP washers” to make their products market-ready for key export markets such as Germany.

Today, this is changing rapidly. More cultivators are moving toward integrating EU GMP-certified processing directly in Colombia. This shift allows producers to retain more value in-country, maintain tighter control over product quality, and export directly to high-demand destinations such as Germany, Portugal, and the Netherlands.

Market Growth and Global Position

The total Colombian cannabis market is projected to reach between USD $68.16 million and USD $72.57 million by 2025, depending on how the market is defined and segmented. Looking ahead to 2030, forecasts suggest growth to be as much as USD $146.7 million, representing a Compound Annual Growth Rate (CAGR) of 27.7%. For the medical cannabis segment alone, 2025 revenue is expected to be at least USD $21.56 million, with a projected CAGR of 4.55%.

Sources for Colombian Cannabis Market Data

- Statista – Cannabis Market in Colombia (Total, 2025: USD $68.16M)

- Cognitive Market Research – Medical Cannabis Market Report (2025: USD $72.57M)

- Grand View Research – Legal Cannabis Market in Colombia (2030: USD $146.7M, CAGR: 27.7%)

- Statista – Medical Cannabis Market in Colombia (2025: USD $21.56M, CAGR: 4.55%)

The Role of Microbial Safety in Colombia’s New Era

Post-harvest microbial control is vital for complying with EU GMP standards and accessing premium European markets. At Ziel, our Radio Frequency (RF) decontamination technology helps cultivators meet these strict European Pharmacopoeia guidelines, opening the door to key destinations like Germany, Portugal, and the Netherlands.

By combining GACP-certified cultivation with local EU GMP processing and advanced microbial safety solutions like ours, Colombia is moving from a raw material supplier to a fully integrated, premium medical cannabis exporter. This transformation reflects a strong commitment to quality and global compliance, marking a new chapter for the country’s cannabis industry.

We’re proud to partner with producers who are ready to meet the strictest European standards and expand their reach worldwide.

Talk to Ziel about supporting your EU GMP transition today!

Germany Cannabis Remediation,

Regulations + Market Updates

Germany’s adult-use market hit its one-year anniversary on April 1, 2025. As expected, the industry exploded over its first 365 days.

Both recreational and medical markets are seeing massive increases in consumer demand, which has led to a surge in imports from Canada, Portugal, the Netherlands, and other countries. Q4 2024 saw a rise in imports by 53% compared to Q3 2024 and 272% compared to Q4 2023. [1]

In 2025, Germany’s cannabis industry is expected to earn around €1 billion in revenue.[2]

Germany’s Current and Future Cannabis Supply

As its industry continues to boom, Germany will continue to import the majority of the cannabis products it sells.

When the CanG reform bill passed in April of 2024, it opened up domestic production within Germany. Previously, only three operations had been federally approved within the country’s borders. Still, it’s expected to take years for domestic production to be fully scaled and able to support German consumer demand. In the meantime, the country will maintain its reliance on imports from other countries.

Germany approaches its cannabis industry the same way it approaches pharmaceuticals, meaning anyone who wants to import to or produce within the country must meet strict regulatory requirements.

Germany Cannabis Remediation:

Exporting/Importing Requirements

Like any pharmaceutical product sold in Germany, cannabis manufacturers must earn an EU-GMP certification for their facilities.

The EU-GMP certification process reviews every part of production, from major components like the machinery used and the procedures followed, to smaller items like ensuring the proper signage has been placed around the facility. The goal of the EU-GMP certification is to guarantee that the process used to produce a particular product is repeatable and consistent, making the same product every time.

A major part of that review is microbial compliance, around which Germany has the strictest requirements in the world. Their laws address topics like:

- Cannabinoid Content: The total THC and CBD levels in a product must not deviate by more than ±10% from labeled values, ensuring consistency and consumer safety.

- Foreign Matter: The presence of seeds, insects, mold, or other contaminants is prohibited.

- Heavy Metals: There are specific limits for arsenic, cadmium, and lead, with stricter thresholds for inhaled products due to higher patient exposure risks.

- Loss on Drying: The maximum allowable moisture content is 12%.

They also require all cannabis flower to achieve the same approved microbial limits as is allowed for all Herbal Drugs under their Pharmaceutical Monograph. This requires operators to remediate their flower. [3]

Cannabis remediation falls into two categories: ionizing and non-ionizing. German regulators prefer non-ionizing technologies because they’re safer for the product and the consumer, and because of this, they entice operators to use them over ionizing options.

Germany Encourages Non-Ionizing Remediation for Cannabis

Ionizing radiation, such as gamma, e-beam, and X-ray technologies, alters the molecular structure of the plant. Operators who decontaminate their flower using these options must apply for an AMRadV license for every cannabis strain they treat before that strain can be sold in Germany. This process is costly (around €4,500 per license) and slow, often taking up to 12 months for approval.

In contrast, non-ionizing remediation methods like Radio Frequency (RF) do not require AMRadV licensing. Because non-ionizing technologies do not affect the molecular integrity of the plant, they’re considered a gentler, safer, and more regulatory-friendly option.

As Germany’s cannabis market scales, cultivators and importers are increasingly seeking non-ionizing cannabis remediation options to ensure faster compliance, reduce regulatory risk, and save money.

Ziel RFX: The Compliance Solution

for Germany Cannabis Remediation

Radio Frequency works by penetrating the cannabis flower with long, low-energy wavelengths. The vibration from these radio waves causes the water molecules inside the plant to vibrate in unison, generating enough heat to kill microbial pathogens without harming the plant’s chemical compounds.

Choosing non-ionizing technology like RF to achieve microbial compliance is the most cost-effective solution for those looking to export cannabis to Germany. The technology has already been approved for USDA Organic operations in other industries and is currently being used in EU-GMP certified cannabis productions in Europe, making it easy to incorporate it into facilities that are already EU-GMP certified or those that are looking to become certified.

Ziel’s RFX machine, the leading Radio Frequency decontamination solution, has the largest throughput of any microbial control solution on the market today, making it ideal for cultivators looking to process large volumes.

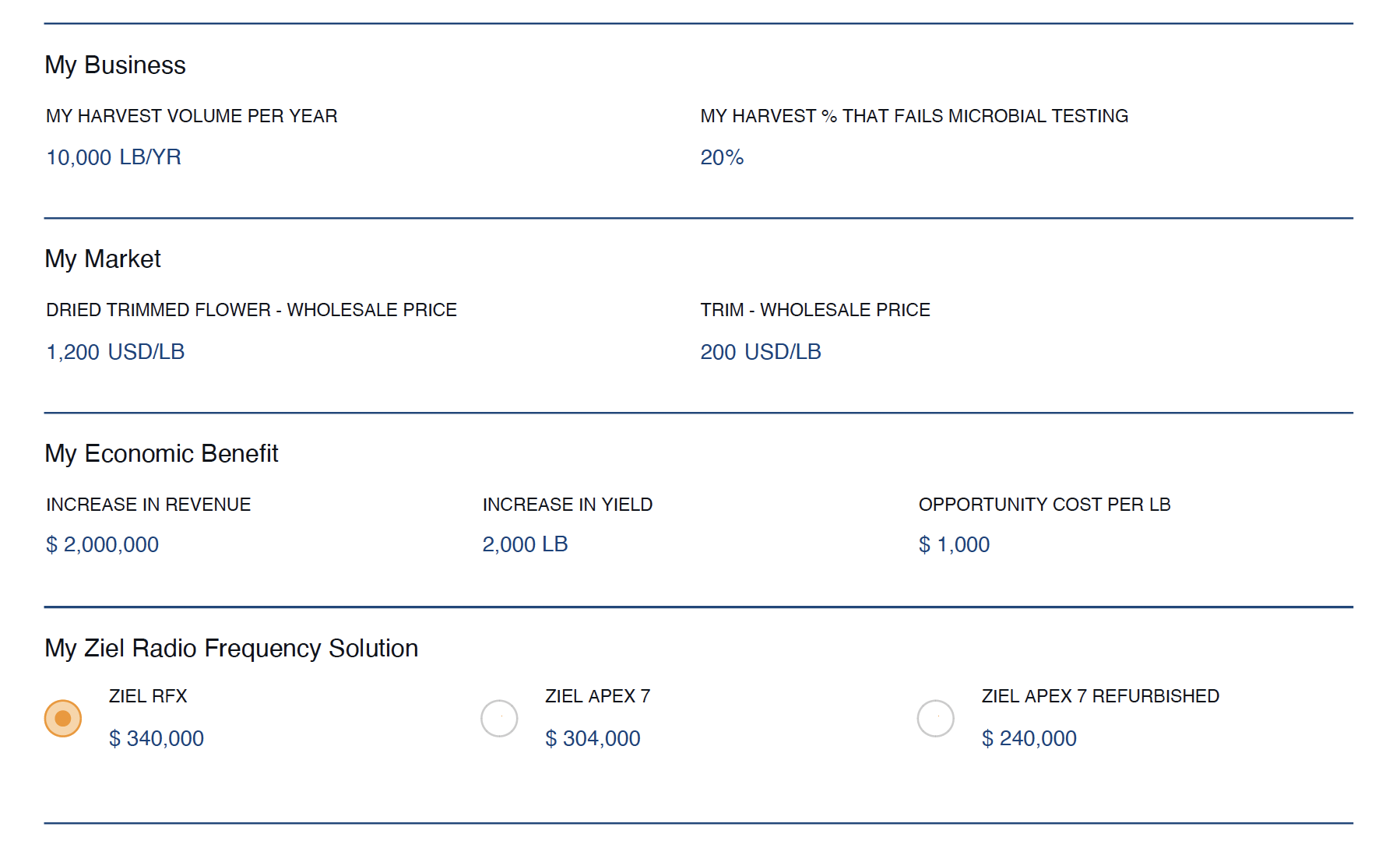

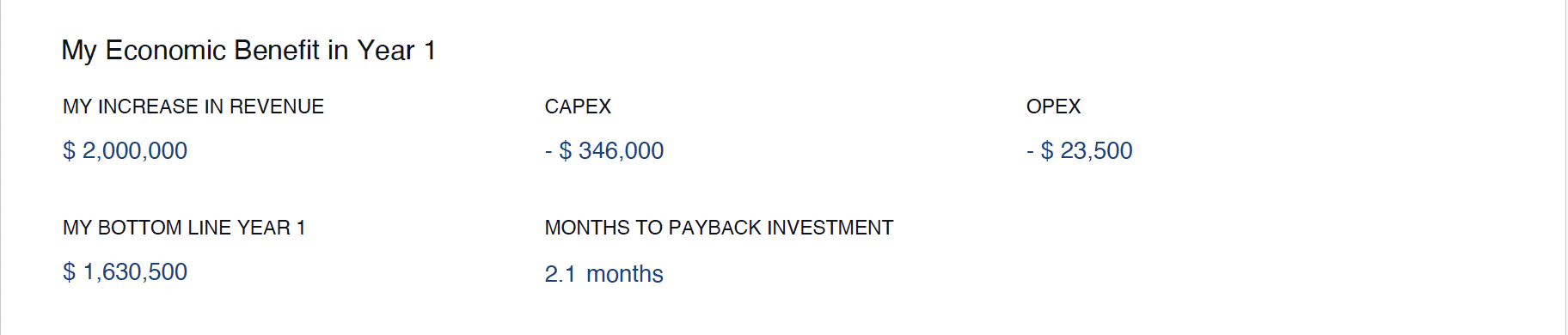

Using Ziel’s Business Case Calculator, cultivators can determine how much revenue the RFX will recover for their business by increasing harvest yields, avoiding compliance failure, and eliminating the need to send contaminated product off to extraction. This, in turn, also eliminates the subsequent costs for retesting. Cultivators interested in exporting to Germany are also encouraged to add up how much they’d spend in time and money on AMRadV licenses for each of their strains treated with ionizing radiation, an expense that’s nonexistent with Ziel’s RF technology.

Cost Savings of Radio Frequency

Cannabis Decontamination with Ziel

To better understand just how much money the RFX can save cannabis manufacturers, explore the example below.

Using a wholesale selling price of €4,000/kg, if a processor failed 20% of their annual harvest, they would be forced to retest, treat again, or offload the failed product to a manufacturer for a deep discount—as much as 90%, or €400. This snapshot shows the revenue a business will recover within the first year of using the RFX, based on recovering 20% of the harvest that fails microbial testing on 1,000 kgs of dry flower harvested annually.

In this example, more than €720,000 of revenue is recovered in the first year alone. That’s more than double the cost of the RFX.

The Future of Germany’s Cannabis Market

Cannabis cultivators looking to join Germany’s market must have a mold treatment solution in place. Radio Frequency is the safest and most cost-effective option on the market, requiring no additional licensing and operating in alignment with EU-GMP processing guidelines.

If you’re looking to streamline your product’s entry and position in the German cannabis market, let’s talk. Ziel’s RFX offers the largest throughput of any technology currently available and boasts a >99% pass rate for regulatory compliance. Together, we can get you set up to leverage what’s shaping up to be one of the largest cannabis markets in the world.

The Hidden Mold Crisis in Cannabis:

Inside "Lab Gate"

The cannabis industry is dealing with a major scandal—some are calling it “Lab Gate.” Testing labs are supposed to protect consumers, but instead, some are helping moldy cannabis pass inspections and land on dispensary shelves.

Take Massachusetts. Labs there have been warning for years that mold-contaminated products are hitting dispensary shelves. But instead of taking action, regulators turned a blind eye—until a consumer advisory last month finally acknowledged the issue. Meanwhile, Colorado is dealing with its own mess. An investigation found massive testing fraud, with labs manipulating results to make products seem safer than they really are.

At Ziel, we believe testing alone isn’t enough if labs are not consistently reliable. That’s why our Apex 7 and RFX decontamination systems go beyond testing—they address mold and pathogens before the product reaches consumers.

Mold Contamination: The Scandal Goes Deeper

Here's the truth: state cannabis testing rules and enforcement are inconsistent. In some states, businesses can get away with selling contaminated products simply because regulators don’t enforce strict enough standards.

In New Jersey, regulators just updated their rules to tighten things up:

- Smaller batch sizes for testing (now capped at 33.07 lbs instead of 100 lbs)

- No more lab shopping—businesses can’t just hop from one lab to another to get the results they want

- Standardized lab testing protocols for pesticides, heavy metals, and mold

But even with tougher regulations, the same tricks are happening in other states.

Colorado’s cannabis industry is riddled with loopholes. A deep dive into 325,000 mold tests found shady patterns—labs were tweaking results to just barely meet legal limits. Even worse, some companies were remediating only their samples before testing to guarantee a pass, while selling the rest of the batch untreated and untested.

And then there’s Massachusetts. Testing labs there warned regulators for years, providing hundreds of data points showing moldy cannabis being sold. The response? Crickets. Some cannabis workers have even reported being told to "just pick out the moldy pieces" and sell the rest. As reported by GBH in their investigative article on mold contamination in cannabis, these warnings were largely ignored by the Cannabis Control Commission despite mounting evidence.

This isn’t just about bad business practices. Mold spores can cause serious health problems, especially for people with respiratory conditions or weakened immune systems. Yet weak oversight allows this problem to continue.

Decontamination: The Only Way to Fix This Mess

Testing is important, but here’s the real question: what happens when cannabis mold counts are above state regulatory limits?

Some companies turn to chemical treatments or irradiation, but those methods can impact the product’s taste, smell, and potency. However, there is a better option..

Ziel’s radio frequency (RF) decontamination technology mitigates mold without damaging the product. The Apex 7 and RFX machines use RF energy to kill mold, bacteria, and other microbes while preserving the flower’s organoleptic qualities.

Cannabis cultivators that use Ziel’s technology don’t have to hope their product is safe—they know it is.

And if you’re a consumer, there are ways to access a Certificate of Analysis (CoA) before you buy. This report shows whether a product was properly tested and free from harmful contaminants. These COAs are available through various channels, including dispensary websites, QR codes on product packaging, in-store access, or by directly requesting them from the producer or dispensary staff.

The Industry Needs to Clean Up Its Act

In order for the Cannabis Industry to succeed, it can’t afford another Lab Gate.

Here’s what needs to change:

- Regulators need to enforce stricter testing rules and crack down on fraud.

- Labs must stop manipulating results—passing moldy products to keep clients happy is unacceptable.

- Cultivators must invest in real decontamination solutions instead of hoping they can slide by with weak testing.

At Ziel, we’re giving cannabis businesses the tools to produce truly clean cannabis—so consumers stay safe and cultivators can protect their brand. Want to address mold contamination for good? Let’s talk.

Contact our team today or visit our website to see how Ziel’s technology can keep your cannabis clean, safe, and trustworthy.

References

*1. LeMoult, C. (2025, February 12). Labs warn mold contamination is more widespread than Cannabis Control Commission has let on. GBH News.

*2. Wyloge, E., & Osher, C. (2025, February 21). Is Colorado cannabis safe? Testing for potency, contaminants riddled with loopholes. The Denver Gazette.

*3. New Jersey Cannabis Regulatory Commission. (2025, February 19). NJ-CRC adopts new cannabis testing guidelines.

*4. Centers for Disease Control and Prevention. (2020). Cannabis Use and Fungal Infections in a Commercially Insured Population, United States, 2016

*5. New Jersey Cannabis Regulatory Commission. (2025, March 4). High Points: Understanding Certificates of Analysis.

MG Magazine's: Breakout Cannabis Cultivation Products for 2025

Mold and other pathogens can be devastating to any cannabis cultivation operation. Ziel’s new RFX remediation machine uses radio frequency technology to clean moldy flower. The non-ionizing technology creates an oscillating electromagnetic field that syncs with the flower’s moisture content, spinning 27 million times per second and creating enough friction to heat and kill microbial pathogens without damaging or decarboxylating THC.

Check out the full article linked here!

From Seed to Sustainability: How Cannabis Companies Are Going Green

The cannabis industry, historically focused on reducing costs, is now at a critical juncture where sustainability is evolving from a secondary concern to a central operational strategy. More operators are recognizing that environmentally responsible practices can be both economically beneficial and essential for long-term viability as consumers look for organic products that are grown and processed responsibly. Companies like Ziel, a leader in the use of radio frequency technology for the decontamination of cannabis flower, demonstrate that sustainable practices and cost-efficiency can align, making a powerful case for greener practices.

The Investment in Sustainability

Implementing sustainable practices often demands upfront investment and resources, but the long-term benefits are significant. Similar to cannabis cultivation, agricultural farmers are going green by incorporating sustainable tech into their operations. For instance, while robotics and AI are no strangers to agriculture, Carbon Robotics is utilizing a LaserWeeder system to help eliminate weeds from various crops—all without relying on toxic chemical herbicides or disruptive soil practices. Carbon Robotics helps farmers reduce the high cost of manual labor while also providing USDA organic farmers with a solution for removing weeds without the use of herbicides. These efforts not only foster a loyal customer base dedicated to environmental responsibility but also establish the farmer and tech providers as leaders in the organic sector.

The Path to Certification

Currently, cannabis products lack the ability to be USDA Organic certified due to the plant’s federal status as a controlled substance. However, with the potential for cannabis to be reclassified as a Schedule III substance, there will be an opening for FDA oversight, which could pave the way for USDA and National Organic Program (NOP) standards to apply to cannabis cultivators in a similar manner as the agricultural food industry. If this occurs, cannabis products adhering to these standards may finally earn organic certification, aligning with the guidelines currently applied to food and supplements. Not only do cultivation protocols determine organic certification, post-harvest processes impact certification as well. Therefore, selecting a microbial control solution technology that is compliant with organic processes is critical.

Sustainable Microbial Control Methods

Radio frequency is a non-ionizing radiation treatment that has been used to pasteurize food products for decades. It is considered safe for consumer consumption by the FDA and USDA, as well as compliant with NOP organic processes. Products treated with ionizing radiation are ineligible for organic certification under USDA and FDA guidelines. In Canada, the Radura symbol is required for both food and cannabis products exposed to ionizing radiation like gamma, e-beam and X-ray options. These treatment methods are effective but controversial, as ionizing radiation can alter the molecular structure of cannabis, potentially impacting its terpene profile and other active compounds.

A non-ionizing treatment like radio frequency technology offers several advantages for sustainable cannabis processing. Unlike traditional decontamination methods that are energy and resource intensive, the Ziel RFX requires only electricity and processing bags—eliminating the need for chemicals or waste disposal. For instance, the RFX can decontaminate 160 lbs of cannabis in just 8 hours for under $10 in electricity, reducing environmental impact while boosting energy efficiency.

Conversely, ionizing cannabis remediation technologies have other associated costs outside of regulations. For example, e-beam and gamma remediation must be done off-site, costing cultivators time and money for transportation, insurance, and administration. X-ray equipment can be installed on-site, though it does require the installation of additional chiller equipment, adding cost and an additional layer of initial permitting and annual renewals. Radio Frequency remediation, on the other hand, doesn’t call for any extra licensing, labeling, or facility upgrades. It can be done on-site, and the technology has already been screened by the USDA in other applications.

Lastly, the Ziel RFX device is designed with a lifespan of over 20 years, eliminating the need for frequent parts replacements and significantly reducing waste. Unlike other market options, which often require ongoing repairs or major modifications to facilities, the RFX is a durable, cost-effective solution that supports both sustainability and operational efficiency in the long term.

Technologies like radio frequency, provide a sustainable solution for microbial control that aligns with both U.S. and Canadian organic guidelines and with Good Manufacturing Practices (GMP) certified operations in the U.S. and E.U.

Pathways to Sustainable Certification

As the industry awaits the possibility of federal organic certification, cultivators can seek alternative credentials. Programs like Envirocann and EnvirOganic, are geared toward those with strict adherence to sustainable farming practices and manufacturers who follow strict compliance in a laboratory setting, GMP, and environmental awareness. Coastal Sun Farms, in California, exemplifies this approach with its commitment to ecological farming.

Another prominent option is the Clean Green Certified program, the largest and most awarded cannabis certification, promoting sustainable practices. CULTA, a Maryland-owned craft cannabis brand, was the first farm in the state certified by Clean Green for its no-till farming methods and integrated pest management, which includes the use of beneficial insects in the live soil.

Beyond Cultivation: Sustainable Sourcing

Sustainability is not limited to cultivation. Many companies incorporate ethical sourcing practices into their supply chains. Grön, a cannabis edibles brand, achieved a milestone in 2019 as the first cannabis chocolate brand to receive Fair Trade certification, supporting sustainable income for cocoa farmers and their communities.

The Future of Sustainable Cannabis

As environmentally responsible practices continue to gain momentum in cannabis, the industry is moving toward more sustainable hardware and ethical processes. Cultivators and manufacturers adopting eco-friendly methods—whether through certification programs, Fair Trade sourcing, or energy-efficient technology—are setting the stage for cannabis to become a model of ethical and sustainable operations. This dedication will not only enhance consumer trust but also contribute to a greener, more sustainable future for the industry and the planet.